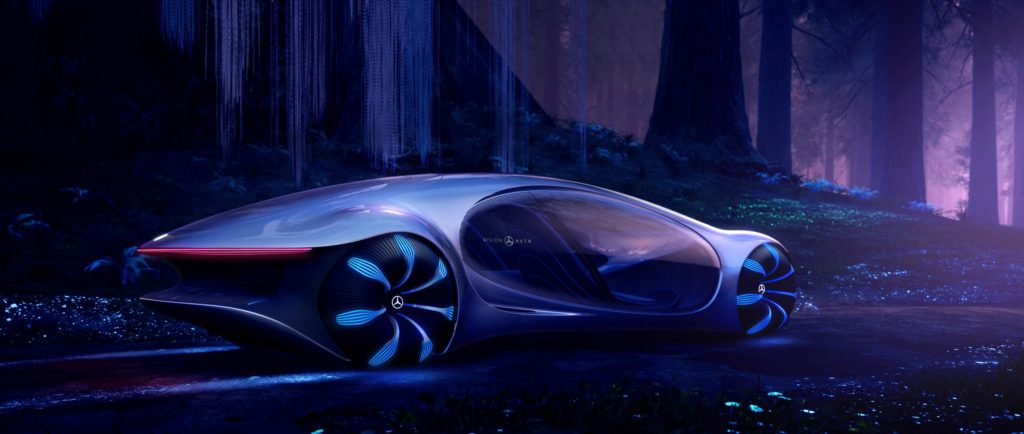

Mercedes-Benz «Vision AVTR»

VISION AVTR – inspired by AVATAR.

Detroit Auto Show, er flyttet fra januar, til juni. Ikke så rart når vi så nedgang på besøk år for år. Da får man trøste seg med bilnyheterne som dukker opp på CES-messen i Las Vegas…. Mercedes har tatt den helt ut 😉

The name of the groundbreaking concept vehicle stands not only for the close collaboration in developing the show car together with the AVATAR team but also for ADVANCED VEHICLE TRANSFORMATION. This concept vehicle embodies the vision of Mercedes-Benz designers, engineers and trend researchers for mobility in the distant future.

Extremely confident – and completely without emissions.

With its four high-performance and near-wheel-built electric motors, the VISION AVTR embodies a particularly agile implementation of the vision of a dynamic luxury saloon. With a combined engine power of more than 350 kW, the VISION AVTR sets a new benchmark for EQ Power. Thanks to the intelligent and fully variable torque distribution, the power of the four fully individually controllable motors is not only managed in the best possible way in terms of driving dynamics, but above all in a highly efficient manner. The innovative all-wheel drive with torque vectoring enables completely new freedoms and guarantees driving dynamics at the highest level while at the same time providing the best possible active safety. This means that each wheel can be driven separately and depending on the driving situation. Due to the possibility to drive the front and rear axles simultaneously or in opposite ways, the VISION AVTR can move sideways by approx. 30 degrees, in contrast to conventional vehicles. The so-called “crab movement” gives the concept vehicle a reptile-like appearance even in its movement.

Organic battery technology.

The VISION AVTR was designed in line with its innovative electric drive. This is based on a particularly powerful and compact high-voltage battery. For the first time, the revolutionary battery technology is based on graphene-based organic cell chemistry and thus completely eliminates rare, toxic and expensive earths such as metals. Electromobility thus becomes independent of fossil resources. An absolute revolution is also the recyclability by composting, which is 100% recyclable due to the materiality. As a result, Mercedes-Benz underlines the high relevance of a future circular economy in the raw materials sector.

Exceptional fast charging capability.

In addition to an exponentially high energy density – compared to today’s battery systems with up to 1,200 Wh/litre – the technology also impresses with its exceptional fast charging capability via automated, conductive charging technology. This means that the battery will be fully recharging in less than 15 minutes. The innovative technology also allows maximum flexibility with regard to the construction space: with a local minimum of 94 millimetres, the battery adapts ideally to the shared space vehicle concept, thus maximising the multifunctional interior.

With a capacity of around 110 kWh, the VISION AVTR enables an electric range of more than 700 kilometres. By recuperating during roll-out and braking, the high-voltage battery can be recharged with a higher efficiency than established systems while driving and thus contributes to the high energy efficiency of the overall system.

Masterpiece of effiency.

At Mercedes-Benz, the consideration of efficiency goes far beyond the drive concept, because with increasing digitalisation, the performance of the large number of so-called secondary consumers also comes into focus – along with their efficient energy supply, without negatively affecting the drive power of the vehicle itself. Energy consumption per computing operation is already a key target in the development of new computer chips. This trend will continue in the coming years with the growth of sensors and artificial intelligence in the automotive industry. The neuro-inspired approach of the VISION AVTR, including so-called neuromorphic hardware, promises to minimise the energy requirements of sensors, chips and other components to a few watts. Their energy supply is provided by the cached current of the integrated solar plates on the back of the VISION AVTR. The 33 multi-directionally movable surface elements act as “bionic flaps”.

3075

3075